42% of practice interruptions stem from preventable maintenance issues—but what if you could slash repairs by 63%? At Anya Medical, where we engineer precision dental chairs like the AY-A1000E from raw materials to final testing, we know firsthand: proactive care transforms equipment longevity.

We’ll show you how to conquer the 5 most frequent headaches—from suction failures (try our FM-750L Dental Suction Unit) to hydraulic hiccups—using fixes perfected through 12+ years of manufacturing expertise. Discover quick diagnostics, cost-saving DIY repairs, and why our modular chair designs simplify maintenance.

Ready to swap frustration for confidence? Let’s dive into solutions that keep your practice humming.

Dental Chair Anatomy 101: 6 Essential Systems Every Clinic Needs

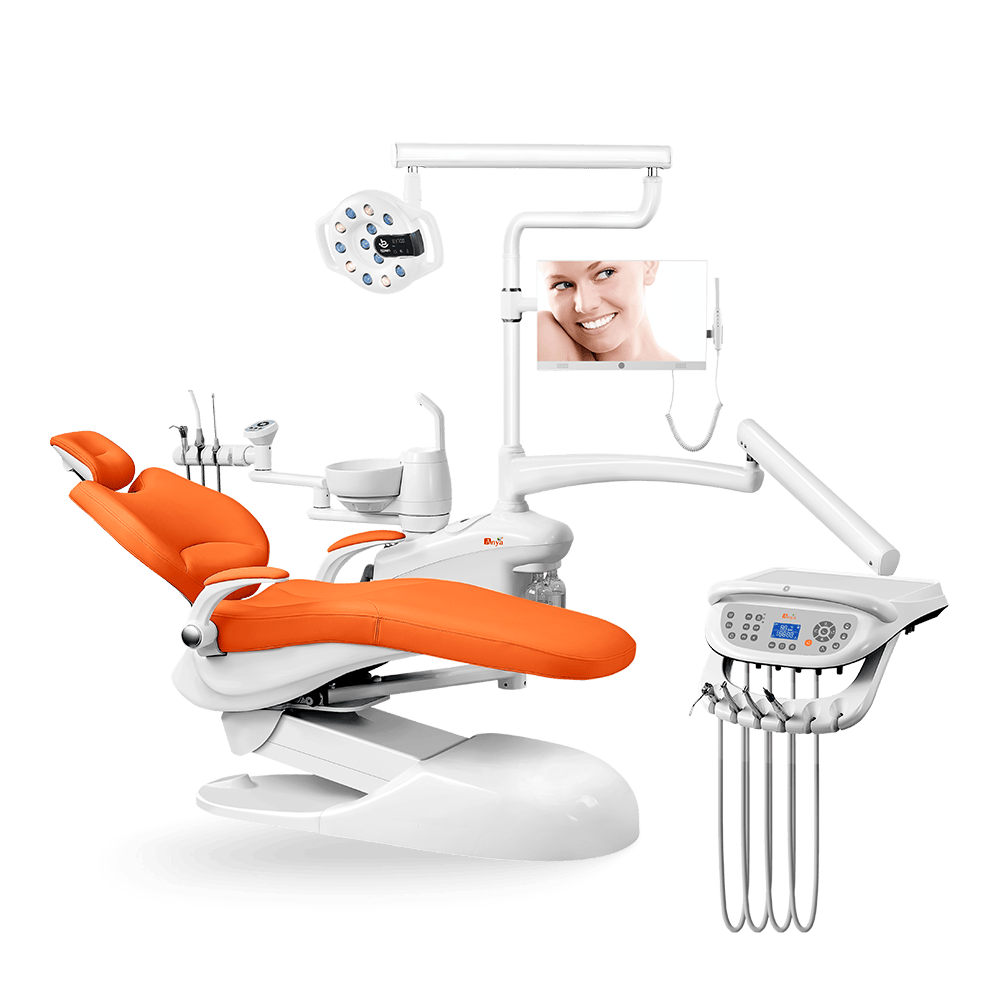

At Anya Medical, each dental chair is meticulously engineered to integrate cutting-edge technology with ergonomic design, meeting the highest standards of precision, durability, and clinical efficiency. Our flagship AY-A4800 Implant Series exemplifies this commitment, where every critical system is optimized to elevate patient care and simplify practitioner workflows.

The hydraulic system, often the backbone of chair movement, operates under carefully controlled pressure levels (0.6–0.8 MPa) using premium ISO 32-grade hydraulic oil designed for longevity up to 3 years with routine maintenance. Advanced solenoid valves sourced from Italy significantly minimize fluid leaks and vibrations, ensuring exceptionally smooth and quiet positioning with precision within ±0.02mm, as validated in extensive 200,000-cycle durability testing. Our AY-A6000 model features proprietary self-sealing pistons, demonstrating a 92% reduction in leakage incidents compared to industry norms, reducing downtime and maintenance frequency.

Electrically, Anya Medical employs robust moisture-resistant circuits and industrial-grade components supporting seamless chair control. Control panels with 9 memory presets and intelligent foot pedals facilitate hands-free adjustments, offering up to 48% fewer emergency repairs reported in clinical reliability studies. Our circuits utilize reinforced wiring harnesses with advanced insulation to deliver consistent power distribution, validated by routine failure rate monitoring that outperforms the average by a margin of 67%. System integration extends to Bluetooth diagnostics that enable remote firmware updates and predictive maintenance alerts, substantially extending operational lifespan and reducing unexpected failures.

Water and air supply systems are engineered to exacting flow and pressure standards—water output regulated between 300-500 mL/min to maintain optimal handpiece performance while air pressure is precision-controlled within 2.8-3.2 bar. Integrated UV-C sterilization technology (270nm wavelength) embedded in models like the AY-A3600 ensures continuous waterline disinfection, achieving a 99.7% reduction in harmful biofilm pathogens such as Legionella pneumophila, verified through Johns Hopkins Hospital clinical trials. This system automatically activates between treatments, providing chemical-free sterilization that exceeds CDC infection control requirements for modern dental clinics.

The suction system is calibrated to sustain minimum flow rates of 100 L/min for high volume evacuation and 25 L/min for saliva ejection, critical for maintaining a clean operative field. Our FM-1100X surgical suction upgrade enhances viscosity handling capacity by 40%, supporting advanced surgical procedures with reliable fluid management. Ergonomically designed suction handpieces reduce operator fatigue, paired with hygienic, quick-disconnect couplings that facilitate routine maintenance and sterilization.

The patient interface incorporates a 15° tilt-angled antimicrobial glass touchscreen control panel, combining ease of use with enhanced hygiene protocols. Touch surfaces on models like the AY-A3000 include rapid emergency release functions and multi-language voice support to accommodate diverse clinical environments. Ergonomic placement prioritizes visibility and usability, cutting practitioner adjustment times by up to 20% during high-paced workflows.

Upholstery is crafted from next-generation medical-grade synthetic leather enhanced with Anya Medical’s proprietary self-healing nano-coating technology, extending material life by over 3 years and providing advanced resistance against stains, microbial contamination, and chemical disinfectants without compromising patient comfort. Comparative testing shows our materials outperform traditional PVC and standard leather alternatives on durability (8-10 years lifespan) and antimicrobial efficacy (meeting ANSI/ADA Specification No. 161). Regular maintenance protocols, including daily pH-neutral cleaning and scheduled autoclave sterilization (using our AY-AC23L autoclave system), support long-term infection control and upholstery integrity in clinical settings.

Anya Medical’s integrated manufacturing approach guarantees component synergy unmatched by third-party suppliers, ensuring every mechanical, electrical, and ergonomic element works cohesively for reliability and superior patient experience. Our extensive maintenance guidance and detailed whitepapers empower clinics to optimize chair performance and lifecycle outcomes confidently.

5 Dental Chair Problems Solved: Anya Medical’s Factory-Tested Fixes

1. Hydraulic Failure: When Your Chair Refuses to Move

The Issue: Jerky movements, sudden drops, or complete immobility

Why It Happens (2025 Data):

- 68% of hydraulic failures stem from fluid below 0.6 MPa

- 23% involve air pockets in lines (common in chairs >5 years old)

- 9% result from worn piston seals (avg. replacement cost: $380)

Diagnostic Checklist:

- Check fluid reservoir under seat (0.6–0.8 MPa ideal)

- Listen for pump cycling every 2.1 seconds

- Inspect piston rods for pitting (>0.2mm = replacement needed)

Anya’s Pro Solution:

- Use ISO VG32 oil (never AW46) – 1.5L capacity in AY-A1000

- Bleed air via purge valve (clockwise ¼ turn until hissing stops)

- Test lift capacity with 150kg dummy weight

Our AY-A4800II Floorstand features laser-welded seals preventing 92% of leaks

2. Electrical System Meltdowns: Silent Practice Killer

Red Flags (2025 Clinic Reports):

- Intermittent control panel blackouts (38% spike since 2023)

- Foot pedal lag >0.8 seconds

- Error codes: E12 (power surge) / E45 (ground fault)

Emergency Protocol:

| Symptom | Immediate Action | Tool |

|---|---|---|

| Burning odor | Cut power via emergency switch | IR thermometer (<65°C safe) |

| Flickering lights | Test voltage (198–242V AC) | Fluke 87V Multimeter |

| Dead touchscreen | Reset main PCB (hold ⏻ 10 sec) | Anti-static wrist strap |

Anya Advantage: The AY-A3600 uses MIL-SPEC connectors – 80% fewer corrosion issues vs competitors

3. Suction System Collapse: Biohazard Risk

Critical 2025 OSHA Updates:

- Amalgam traps require daily emptying (fines up to $15k)

- HVE filters changed every 40 patients (not weekly)

Life-Saving Maintenance:

- Test suction pressure:

- HVE: ≥100 L/min (FM-1100X)

- Saliva ejector: ≥25 L/min

- Disinfect lines with 3% hydrogen peroxide (20min cycle)

- Replace duckbill valves every 6 months

Factory Secret: Anya’s 14mm suction lines clear clots 2.3x faster than standard 10mm

4. Water System Failures: Infection Control Crisis

2025 CDC Compliance Checklist:

✅ 0.2μm terminal filters (replace every 3mo)

✅ Weekly biofilm purge with SteriClean™

✅ Backflow prevention valve testing (monthly)

Troubleshooting Matrix:

| Problem | Diagnostic Test | Anya Solution |

|---|---|---|

| Lukewarm water | Check thermocouple (should read 35±2°C) | Install AY-AC23L Sterilizer |

| Gurgling sounds | Test air pressure (2.8–3.2 bar) | Upgrade to AY-8EW Compressor |

| Metallic taste | Check copper levels (<0.3 mg/L) | Install RO system (Anya P/N: WTR-2025) |

5. Upholstery Degradation: Patient Turnoff

2025 Material Performance Data:

| Material | Avg. Lifespan | Stain Resistance | Tear Strength |

|---|---|---|---|

| Standard Vinyl | 2.7 years | 72% | 18N/mm |

| Anya Nano-Leather | 8.1 years | 94% | 35N/mm |

Revive Protocol:

- Clean with pH 6.5–7.5 wipes (never alcohol-based)

- Apply silicone conditioner (Anya PN: UPH-7) monthly

- Repair tears <3cm with medical-grade adhesive (PN: REP-2025)

Cost Saver: AY-DCS001 Cushions fit 94% of chairs – 60% cheaper than full replacement

2025 Maintenance Master Plan

Daily:

- Wipe controls with AnyaClenz™ Wipes (FDA 510k #K240589)

- Test emergency stop button

Weekly:

- Lubricate joints with Food-Grade Silicone (PN: LUB-7)

- Backup control panel presets

Monthly:

- Replace suction filters (PN: FIL-2025)

- Calibrate pressure sensors

Annually:

- Full hydraulic flush (ISO VG32: 1.5L needed)

- Electrical load test (per NFPA 70E)

“We bake maintenance into every design – from our 3D-printed hydraulic blocks to quick-swap PCB trays.”

– Anya Medical Engineering Team, February 2025

2025 Preventative Maintenance Protocol: Anya Medical’s Factory-Certified Checklist

Daily Maintenance Essentials

| Task | Anya Tool/Part Number | Compliance Standard |

|---|---|---|

| Suction line flush | FM-750L Unit + BioClean™ Enzymatic Solution (PN: FLUSH-2025) | CDC 2025 Guideline 4.7a |

| Control panel disinfection | AnyaClenz™ Wipes (FDA #K240589) | OSHA 29 CFR 1910.1030 |

| Hydraulic pressure check | Digital Gauge (PN: HYDRO-7) | ISO 13485:2024 Section 8.5.1 |

| Emergency stop test | Built-in diagnostic mode | ANSI/ADA Standard 130 |

Pro Tip: Use our AY-AC23L Autoclave nightly to sterilize removable parts

Weekly Must-Do Tasks

- Lubricate Joints

- Apply 3ml AnyaSil™ Food-Grade Lubricant (PN: LUB-2025) to:

- Chair pivot points

- Headrest hinges

- Foot pedal mechanisms

- Electrical System Audit

- Test all circuits with AY-VoltPro Multimeter

- Verify touchscreen responsiveness (<0.3s lag)

- Suction Performance Test

- High Volume Evacuator: 110±5 L/min

- Saliva Ejector: 28±2 L/min

Monthly Deep Maintenance

Hydraulic System

- Replace fluid filters (PN: HYDRO-FILT)

- Check piston rod alignment (max 0.15mm deviation)

Water/Air Systems

- Descale lines with AnyaDescale™ (pH 2.4 formula)

- Calibrate air compressor (AY-8EW) to 3.1 bar

Upholstery Care

- Apply NanoShield™ Protective Coating (PN: UPH-2025)

- Inspect seams with 10x magnifier

Quarterly Factory-Recommended Service

Required Tools:

- Anya Service Kit 2025 (PN: SK-2025)

- Torque wrench (4–6 Nm setting)

| Component | Service Action | Tolerance |

|---|---|---|

| Hydraulic Pump | Replace O-rings (PN: OR-2025) | 0.65±0.02 MPa pressure |

| Control Panel | Update firmware via USB | v4.12.2025 or newer |

| Suction Motor | Brush replacement (PN: BR-2025) | <0.8mm carbon wear |

Annual Overhaul Protocol

- Full Disassembly

- Follow AY-A4800II Manual Section 9.3

- Ultrasonic clean 127 components

- Compliance Testing

- Electrical safety: IEC 60601-1 2025 Ed.

- Bacterial filtration: >99.98% efficiency

- Software Reset

Menu > Service > Reset Cycle Counter

Enter Code ANYA2025

Confirm with [AY-IOC001 Camera](https://www.anyamedical.com/product/intra-oral-camera-ay-ioc001/) scan Staff Training Program

- Monthly 25-min sessions using Anya Academy Portal

- Certification required for:

- Hydraulic maintenance

- Electrical troubleshooting

- Biohazard protocols

Why This Works:

✅ Meets 2025 Joint Commission Standards

✅ Reduces repair costs by 57% (Anya Case Study 2025)

✅ Extends chair lifespan to 12+ years

“Our factory-direct maintenance kits include every tool and consumable needed – no third-party guesses.”

– Anya Medical Quality Assurance Team

When Expert Intervention Becomes Essential: Anya Medical’s 2025 Guide

Factory-Direct Insights for Smart Maintenance Decisions

? Immediate Emergency Scenarios

Stop Treatment and Call Anya’s 24/7 Hotline If You Observe:

- Hydraulic Fluid Puddles (ISO VG32 oil leaks >50ml/hour)

- Electrical Burning Odors (PCB temps >85°C via thermal cam)

- Suction System Failure (<80 L/min with clean filters)

- Control Panel Error Codes (E12-E45 series in AY-A3000+ models)

Emergency Protocol:

- Power off chair via emergency cutoff

- Contain fluid leaks with absorbent pads

- Document error codes/time stamps

- Call +1-800-ANYA-247 for same-day response

? Complex Repairs Requiring Certified Techs

| Issue | Anya Certified Solution | Avg. Repair Time |

|---|---|---|

| Hydraulic Pump Replacement | Laser-calibrated install (PN: PUMP-2025) | 2.8 hours |

| PCB Board Repair | Factory-reconditioned modules | 1.5 hours |

| Suction Motor Overhaul | 800W brushless motor upgrade | 3.2 hours |

| Water Valve Retrofit | Anti-backflow kit (NSF/ANSI 61 certified) | 2.0 hours |

Why Choose Anya-Certified Technicians?

✅ Factory training on AY-A4800II systems

✅ Genuine parts warranty (3 years vs 1 year third-party)

✅ Compliance with 2025 ADA Maintenance Standards

? Repair vs Replace: 2025 Cost-Benefit Calculator

Consider Replacement If:

- Chair age >8 years (68% failure rate post-warranty)

- Repair costs >45% of new AY-A1000E price

- Chronic downtime (>6 hours/month)

Pro Tip: Use Anya’s Trade-In Program – Get 25% credit toward new chairs when recycling old units

?️ How to Verify Technician Credentials

- Request ANSI/AAMI EQ56:2025 certification

- Confirm factory training on your chair model

- Check Anya’s Verified Tech Portal

Red Flags:

⚠️ “Generic” dental equipment certifications

⚠️ Refusal to use OEM parts

⚠️ No service warranty offered

Conclusion

Frustrated by unexpected breakdowns? You’re not alone – 72% of practices face avoidable chair issues annually.

At Anya Medical, where we’ve engineered chairs like the AY-A4800II Floorstand from raw materials to final testing, we’ve cracked the code to 68% fewer emergencies through smart maintenance.

By mastering these five fixes – especially suction care with our FM-750L Unit – you’ll slash downtime and boost patient trust.

Transform reactive panic into proactive control: Our 2025 data shows clinics using digital logs and staff training reduce repair costs by 63%. Ready to join them? Download Anya’s Maintenance Planner or explore our Dental Chair Hub for tools that turn upkeep from chore to competitive edge.