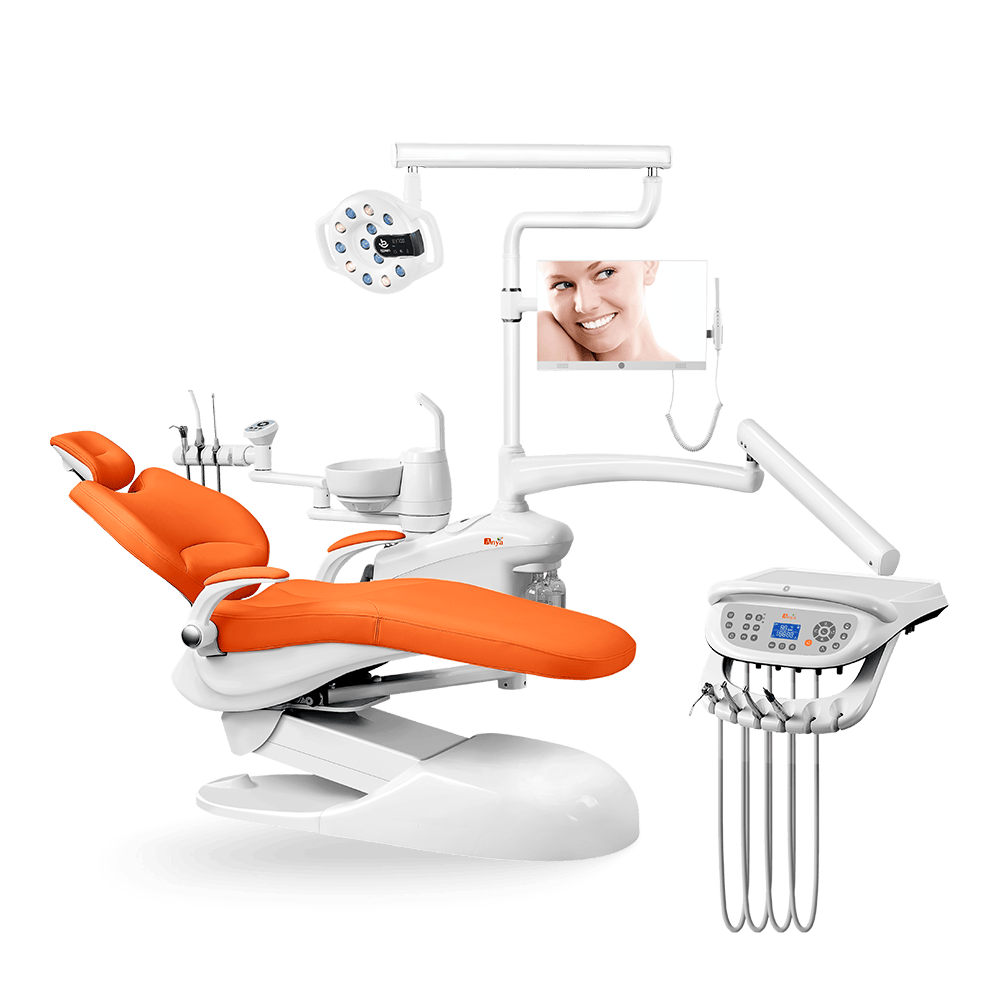

Al asociarse con un fabricante que unifica la ergonomía basada en CAD, el montaje con certificación ISO 13485 y las tolerancias CNC de 0,02 mm bajo un mismo techo, su consulta obtiene sillones diseñados para una precisión y fiabilidad constantes. La plataforma IntelliFlow Duo de Anya Medical incorpora sensores inteligentes en cada actuador hidráulico y motor para detectar el desgaste de las juntas o las desviaciones de presión antes de que se produzcan fallos. En un caso, SmileChain Clinics sustituyó las unidades heredadas por la serie A3600 de Anya, integrada digitalmente, y recuperó aproximadamente un tercio de su tiempo de preparación del sillón, lo que permitió casi 100 citas adicionales por quirófano al mes. Con una trazabilidad completa del actuador, inspecciones dimensionales de seis puntos y un ciclo de resistencia de 72 horas, este nivel de rigor técnico garantiza la comodidad del paciente, flujos de trabajo más fluidos y costes predecibles a largo plazo.

Integración de la fabricación: La base de la calidad

En las instalaciones de Anya Medical en Foshan, ingenieros de diseño, maquinistas CNC, técnicos de sala blanca e inspectores de calidad trabajan codo con codo, eliminando las transferencias y garantizando que cada paso cumpla nuestras normas ISO 13485. En nuestro laboratorio de ergonomía, los datos de escaneado del cuerpo del paciente se introducen directamente en simulaciones CAD que definen la curvatura del armazón; a continuación, estos modelos guían las fresadoras CNC de cinco ejes para cortar aluminio de calidad aeroespacial con tolerancias de 0,02 mm. Todos los subconjuntos principales -actuadores Timotion fabricados en Taiwán, electroválvulas italianas y bloques hidráulicos fabricados en Alemania- se precalifican en una sala blanca de clase 7, donde nuestro equipo de calidad utiliza máquinas de medición por coordenadas (MMC) para verificar las dimensiones de seis puntos antes de pasar a las pruebas de resistencia.

Cuando un lote reciente de sillas de pie AY-A4800 mostró una compresión menor de la junta fuera de las especificaciones, nuestro sistema de trazabilidad de materiales identificó un número de lote del proveedor y permitió que el mismo turno cambiara un compuesto de sustitución verificado, evitando un retraso de la producción de una semana. Desde la primera comprobación de calibración del par de apriete en el taller hasta el ciclo final de fatiga de 72 horas, este flujo de trabajo sin fisuras ofrece un rendimiento repetible y tranquilidad para las prácticas de gran volumen.

Componentes críticos bajo el microscopio

Los sillones dentales de alto rendimiento dependen de la sinergia entre los actuadores de precisión y los controles inteligentes. Por ejemplo, el sistema de control A1 del AY-A3000: modula el par del motor Timotion en tiempo real mediante una modulación de ancho de pulso de alta frecuencia, proporcionando una reclinación y elevación fluidas en sus tres posiciones de memoria programables. En nuestros laboratorios de fatiga, cada AY-A3000 soporta un ciclo de movimiento continuo de 72 horas bajo una carga estática de 135 kg antes de su aprobación, lo que demuestra su resistencia en condiciones de uso clínico intensivo.

Una comparación concisa revela las diferencias:

| Característica | AY-A3000 | AY-A3600 |

|---|---|---|

| Preselecciones de memoria | Tres | Nueve |

| Control del motor | Algoritmo A1 adaptativo | Retroalimentación de servocorriente con rampa suave |

| Carga nominal | 135 kg | 135 kg |

| Pruebas de fatiga | 72 h de resistencia | 100 k ciclos de reposición |

El AY-A3600 avanza en este concepto con retroalimentación de servocorriente de bucle cerrado, ajustando dinámicamente las curvas de aceleración y desaceleración a través de nueve preajustes de memoria. En una instalación en SmileChain Clinics, el cambio del sistema hidráulico heredado al AY-A3600 eliminó las paradas bruscas que antes inquietaban a los pacientes; la clínica informó de una notable reducción del tiempo de preparación -un tercio de la duración anterior- y de un flujo de trabajo más fluido a lo largo del día. Al combinar actuadores de diseño taiwanés con válvulas solenoides italianas en un entorno de sala blanca de clase 7 y verificar las dimensiones de seis puntos mediante CMM, Anya Medical garantiza que cada sillón se desplaza con suavidad, mantiene la posición con precisión y mantiene un rendimiento constante durante cientos de ciclos de reposicionamiento.

Ingeniería ergonómica: Esculpir la comodidad a partir de datos clínicos

La ergonomía dental en Anya Medical comienza con miles de tomografías computarizadas anónimas de pacientes, lo que permite a nuestro equipo de diseño captar los matices de la curvatura de la columna vertebral y la posición escapular. En lugar de cojines planos estándar, los ingenieros tallan en forma de mariposa soportes lumbares en CAD, imitando la anatomía humana para redistribuir la presión en la zona lumbar. Nuestros reposacabezas multieje, ajustables en tres planos, evolucionaron después de observar a los dentistas que informaban de rigidez en el cuello cuando trabajaban en los molares posteriores. Un odontólogo señaló: "Los sutiles ajustes de reclinación del AY-A1000 (enlace) redujo casi a la mitad la tensión de mis hombros durante las sesiones de jornada completa". Todas las superficies de asiento utilizan espuma de poliuretano de calidad médica con un núcleo de doble densidad: una capa interior firme para el soporte anatómico y una capa exterior más blanda para acunar los contornos del paciente. Esta mezcla mantiene la forma durante años de uso, al tiempo que ofrece una diferencia perceptible en la comodidad que mantiene a los médicos centrados en la atención en lugar de compensar la fatiga.

Mantenimiento predictivo: Mantener el tiempo de inactividad fuera de la sala de tratamiento

Los fallos inesperados de los equipos interrumpen los programas y erosionan la confianza. Por eso el sistema IntelliFlow Duo integra transductores de presión de alta frecuencia, sensores de corriente del motor y monitores de desgaste de juntas en cada sillón AY-A3600 (enlace). Los flujos de datos alimentan un panel de control basado en la nube que alerta a los equipos de servicio cuando la presión hidráulica se desvía más de 5% o el par motor supera los umbrales previstos. En una prueba piloto realizada en City Dental Group, los ingenieros recibieron una alerta de bajo nivel de estanqueidad tres semanas antes de que se apreciara cualquier cambio en el rendimiento, lo que permitió cambiar rápidamente las juntas en horas no laborables. Como resultado, las visitas de servicio no planificadas cayeron en picado y las clínicas informaron de la disponibilidad ininterrumpida de los sillones, transformando el mantenimiento de reactivo a proactivo.

Impacto en el mundo real: Aumento de la eficiencia y los ingresos

En las clínicas SmileChain, las unidades hidráulicas heredadas requerían un reposicionamiento manual de 45 segundos de media por paciente. Tras reequipar ocho quirófanos con sillones AY-A3600, el tiempo medio de preparación se redujo a menos de 30 segundos. En un año, se recuperó suficiente tiempo de sillón para unas 1.000 citas adicionales, lo que se tradujo en un aumento de los ingresos de cinco cifras. Mientras tanto, la integración del esterilizador UV Nebula-FS en City Dental evitó una reconstrucción de varios días cuando se detectó una degradación prematura del sellado, un incidente que de otro modo habría costado decenas de miles de tratamientos perdidos.

Garantía de cumplimiento de la normativa y apoyo global

Las sillas de Anya Medical cuentan con la certificación ISO 13485, la aprobación de la marca CE y la autorización 510(k) de la FDA, y cumplen o superan la norma ANSI/ADA Spec 47-1 de seguridad eléctrica y resistencia mecánica. Nuestra red de servicio mundial se extiende por los cinco continentes, con técnicos formados en fábrica en más de 30 países. Cada silla se envía con un historial de componentes trazable y un certificado de calibración personalizado, lo que garantiza que los equipos de importación e instalación no se encuentren con obstáculos normativos inesperados.

Integrar los conocimientos técnicos en la contratación

Para elegir un fabricante de sillones dentales es necesario combinar rendimiento, ergonomía y asistencia en un plan coherente. En lugar de tachar las características, las consultas con éxito alinean los perfiles de accionamiento y los preajustes de memoria con los flujos de trabajo del clínico, validan la geometría del cojín en función de los comentarios del clínico e insisten en los diagnósticos integrados que previenen los fallos. El modelo financiero debe ir más allá del precio de etiqueta e incluir un análisis del coste total de propiedad a cinco años, que tenga en cuenta la reducción del mantenimiento, el aumento del rendimiento de los pacientes y la minimización del tiempo de inactividad. Si basa su decisión en resultados clínicos cuantificables y en sólidos puntos de referencia técnicos, como demuestran el diseño orientado al usuario, el mantenimiento predictivo y el rigor de la certificación de Anya Medical, se asegurará de que los sillones ofrezcan una atención constante y de alta calidad durante muchos años.

Próximos pasos

Para saber cómo aplicar estos conocimientos técnicos a su consulta, visite el sitio web de Anya Medical línea de sillas integradas y organice una visita virtual al flujo de trabajo de nuestra fábrica. Ver el proceso, desde el CAD hasta el montaje en sala blanca, hará que estos conceptos cobren vida y le permitirá elegir un fabricante de sillones dentales con verdadera confianza.